A hundred years ago, it took elbow grease and effort to move heavy-duty equipment. If you didn’t have enough men to do it, the equipment wasn’t moving. With the advent of heavy-duty casters, that all changed in a heartbeat. Now, no matter how heavy equipment might be, it can be moved when the correct caster is chosen. It’s been said that with the implementation of side mount casters the world could be moved. The sentiment is correct.

However, it is important to choose the appropriate caster for the type of equipment. TCH is a top supplier and distributor of side mount casters to manufacturers across the country.

Two Main Categories of Casters

Casters fall into two main categories. Those categories are listed below:

- Rigid

- Swivel

Rigid Casters

Just like when the wheel was developed, its full potential wasn’t realized until mankind figured out how to make them turn. Rigid casters were a great option, when they were first developed, however they were quite limited. They can’t swivel or rotate, which means they can only move forward and back. This makes them great for institutional equipment and medical institutions.

Swivel Casters

When swivel casters were developed, limited maneuverability was no longer a problem. With the increased ability to maneuver heavy equipment, swivel casters have taken over.

Types of Casters

Even though there are two main categories of casters, they have been utilized to develop several different types of casters. Each one has specific benefits, depending upon the application.

Below are listed the five most popular types of casters:

- Stem Casters

- Plate Casters

- Leveling Casters

- Pneumatic and Solid Rubber Casters

- Side Mount Casters

Stem Casters

Typically, the name of the caster is used to refer to how the caster will be attached to the various pieces of equipment. In the case of the stem caster, a rod, or stem is attached to a plate to the bottom of the equipment. The stem is then attached to the physical wheel or caster. In most cases they have a rubber caster wheel. This type of material is chosen so when the equipment is moved, it won’t scratch the floor.

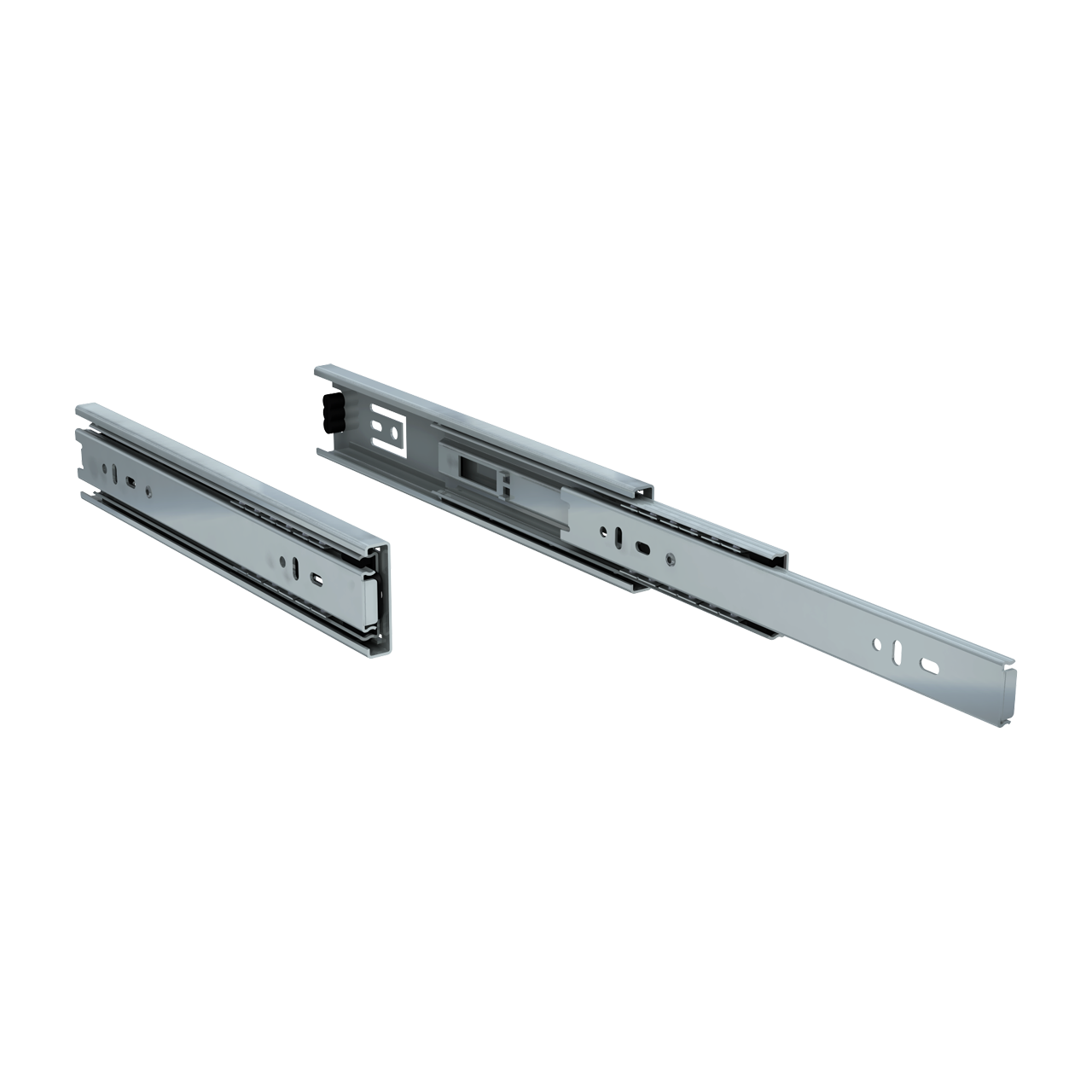

Plate Casters

These are mounted to a flat plate which means they can support more weight with industrial heavy-duty caster wheels.

Leveling Casters

These casters are adjustable to raise or lower the equipment to the appropriate height. These could be used on chairs or vending machines.

Pneumatic and Solid Rubber Casters

These are used for delicate equipment. They are designed for slow moving equipment.

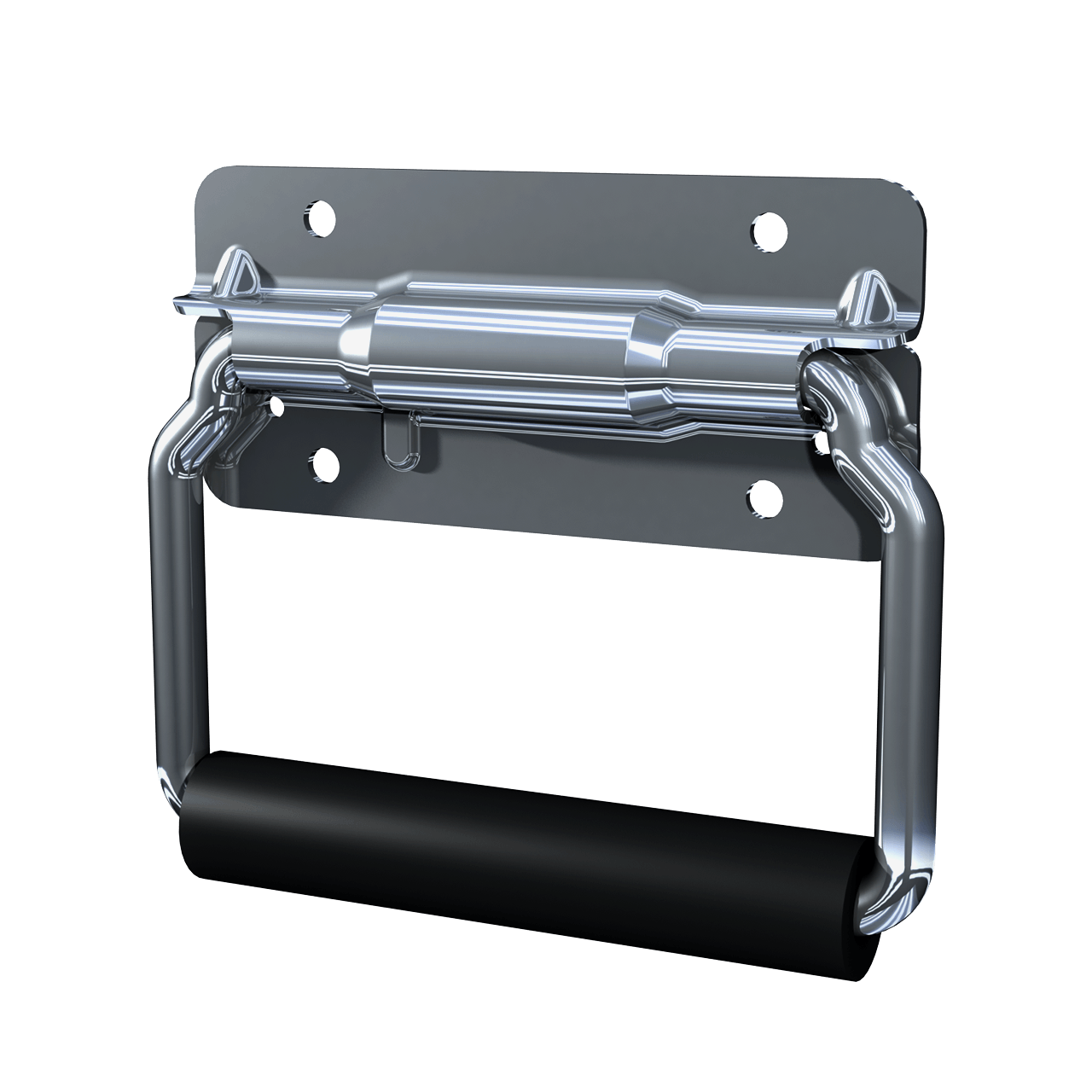

Side Mount Casters

Instead of mounting the caster to the bottom, these are turned vertical and installed along the sides. These can be found on gates, as well as, furniture.

Reach out to TCH for proper caster guidance. We offer the best in selection and quality.